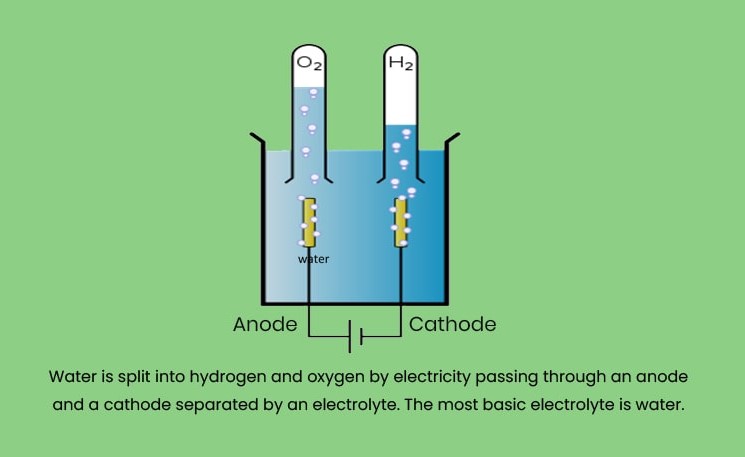

Water is split into hydrogen and oxygen by electricity passing thorugh an anode and a cathode seperated by an electrolyte. The most basic electrolyte is water.

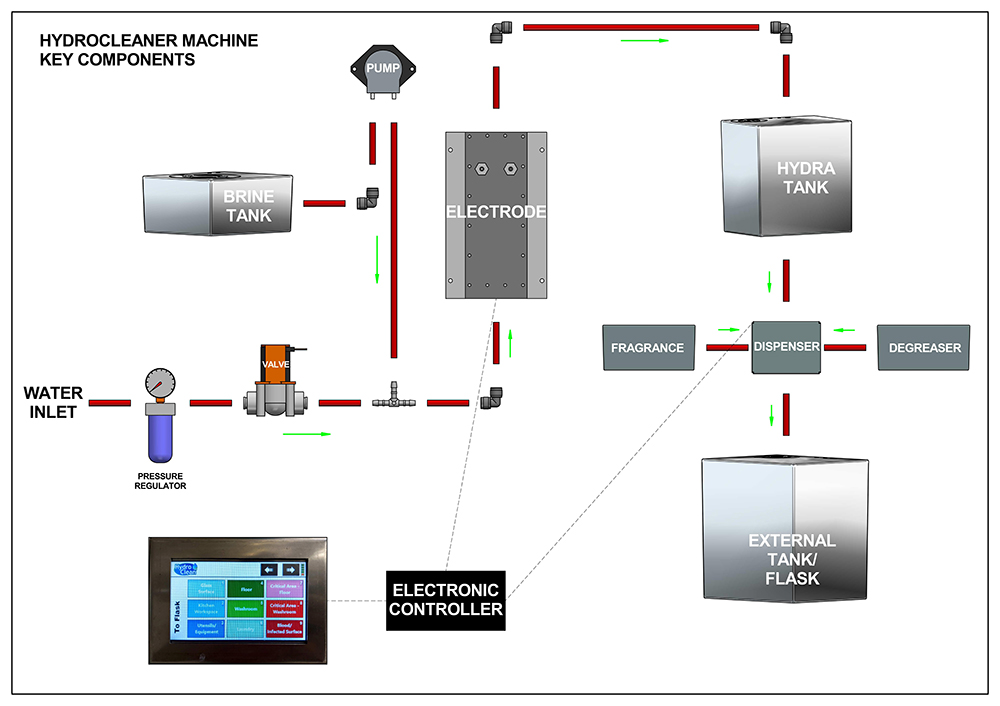

The HydroCleanTM electrolysis process produces one concentrated solution (the Hydra) that goes in a tank. The dispenser diluties the Hydra and can add, if requested, aroma and a degreaser, according to the chosen application (floor, kitchen table, windows glass, etc).

The HydroCleanTM produces one product per application, that can be used for both cleaning and disinfection in a single step, without the need for first wet cleaning the surface and then disinfecting in a second step as is the case with current electrolysed water (EW) technologies.

The oxidant contained in the Hydra constitute powerful biocides. To date no virus, bacteria or fungi has been able to develop any adaptive resistance to the HydroCleanTM .

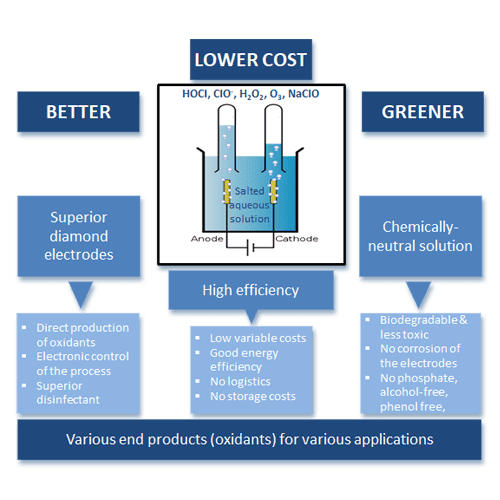

Benefits of The HydroClean™ electrolyzed water solutions for varoius cleaning and disinfection applications

Electrolysed water acts as a very effective disinfectants against microorganisms such as bacteria of all kinds, viruses, fungi, spores and algae.

The HydroClean™ electrolysed water solutions are produced in-situ on a “produced-as-needed basis” – requires no stabilizers for longer shelf-lives. After evaporation, the product rapidly breaks down entirely to salt water and is not harmful to septic and waste-water treatment system.

The HydroClean™ electrolyzed water solutions replace toxic chemicals for cleaning and disinfection.

The HydroClean™

electrolysed water solutions compare favourably to cleaning and

disinfection products: economical, more effective, and with a

lower environmental footprint:

- natural ingredients: water and salt (NaCl 99.5%

purity);

- less toxic end-product: electrolysed water;

- in-situ production: less transportation and storage,

less plastic

packaging waste disposal.